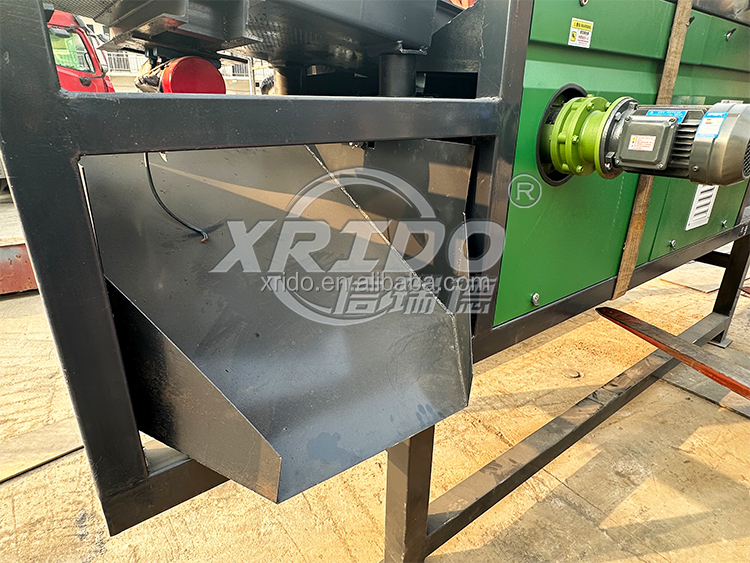

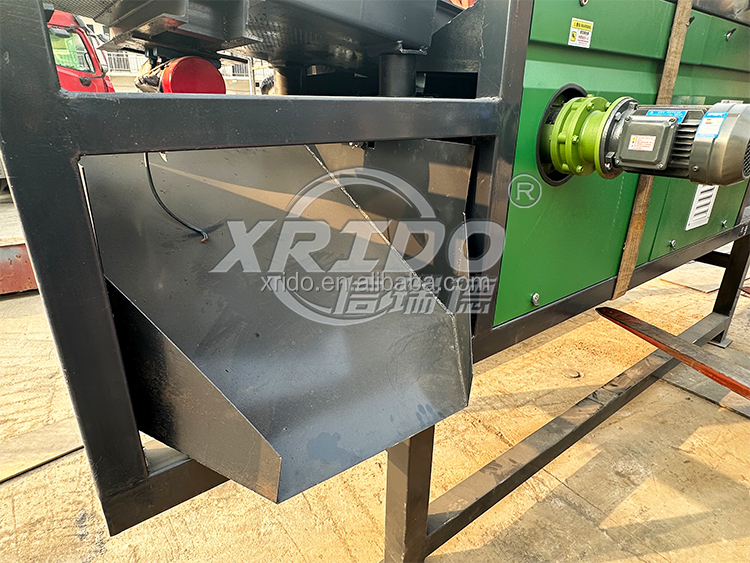

Non Ferrous Eddy Current Separator Machine for Aluminium Recycling

Eddy Current Separator Machine

The permanent magnet drum of high capability rotating inside the

conveyor belt at high speed induces the eddy current in

non-magnetic nonferrous metals moving on the drum to generate a

magnetic field. This force is exerted in the opposite direction to

gravity, and nonferrous metals bounce off by repulsive power from

mixed wastes during movement on the conveyor belt. Non-Ferrous

metals with larger surface areas, lighter weight and higher

conductivity are usually well separated. The separator requires

virtually no maintenance and guarantees the stable separation for

long-term operation. The Non-Ferrous Separator is installed

together with a permanent magnetic separator on MSW to play an

important role for sorting waste.

Eddy Current Separator (Non-Ferrous Separator) is to separate

non-ferrous metals by the induction principle (eddy current) of a

high-frequency magnetic field. The powerful moving magnetic field

on the surface of the drum is generated when the powerful permanent

magnet inside the drum rotates at high speed, separating three

types of materials: iron, non-metal, and nonferrous metals such as

aluminum and copper.

Key Features and Benefits of the Eddy Current Separator

• Precision Engineering: Our separator is manufactured with

precision to ensure high-speed rotor operation with minimal

vibration. The rotor spins at up to 3000 RPM, capable of handling

even the smallest electronic components.

• Powerful Eddy Currents: Equipped with high-performance magnets,

our separator generates a powerful magnetic field of up to 3000

Gauss, ensuring efficient and precise metal separation.

• Durable and Efficient Separation System: Our advanced separation

system accurately identifies and separates non-ferrous metals like

aluminum, copper, and zinc, handling a wide range of waste

materials.

• Automated Control: The fully automated control system minimizes

operator error and ensures optimal performance, reducing downtime

and operating costs.

• Environmental Friendly: Our separator features a fully enclosed

design to reduce dust emissions and maintain a clean working

environment, contributing to a sustainable future.

| Model | Flat belt conveyor(HP) | entrance size (mm / in) | Polar wheel drum(HP) | workload (Kg) | vibrating screen(HP) |

|---|

| X600 | 2 (1.5kW) or 3 (2.3kW) | 600 / 23.6 in | 7.5 (5.6kW) | 400~800 | 1/2 |

| X800 | 2 (1.5kW) or 3 (2.3kW) | 800 / 31.5 in | 10 (7.5kW) | 500~1000 | 1/2 |

| X1000 | 2 (1.5kW) or 3 (2.3kW) | 1000 / 39.4 in | 10 (7.5kW) | 600~1200 | 3/4 |

| X1200 | 2 (1.5kW) or 3 (2.3kW) | 1200 / 47.2 in | 10 (7.5kW) | 700~1400 | 3/4 |

| X1500 | 2 (1.5kW) or 3 (2.3kW) | 1500 / 59 in | 15 (11.3kW) | 800~1600 | 1 |

| X1800 | 2 (1.5kW) or 3 (2.3kW) | 1800 / 70.9 in | 15 (11.3kW) | 1000~2000 | 1 |

*This is the basic model of our Eddy Current Separator machine. Our

factory manufactures customized machines according to the different

requirements of different customers.

|  |

Triple protection for bearings The bearings are sealed and highly corrosion resistant.Cooling with

coolant prolongs service life.With thermal protection function, it

automatically trips when the temperature is too high. | It uses high-strength permanent magnet Nd-Fe-B as the magnetic

source, with stable and lasting magnetic properties and unique

magnetic syste arrangement, which can effectively sort 2mm2 fine

materials. |

|  |

Frequency conversion control The frequency conversion control belt speed is adjustable, the

filter screen gap is adjustable, suitable for materials of different volumes | Made of carbon steel The fuselage is made of carbon steel with spraying technology,which

is durable. |

Eddy Current Separation (ECS) is the use of the different

electrical conductivity property of material.the principle of

sorting isto use a magnet composed of permanent magnets simplified

and high-rotation Producing a magnetic field with

alternatingchanges in the county ,when the metal with electrical

conductivity pass the magnetic field , an eddy current itself will

Alternatethe magnetic field is changed ,and the direction of the

magnetic field generated By the rotation of the magneti is reserved

,insteadof no-iron metal (such as Aluminum ,copper )Will jump out

in the direction of its selection due to repelling ,and thus with

otherbroken glass,plastic Non-metallic substances materials are

separated to achieve the purpose of sorting.

Applications

• Electronic waste recycling: Separate valuable metals from

electronic scrap.

• Automotive recycling: Recover non-ferrous metals from end-of-life

vehicles.

• Metal shredding: Process shredded metal to extract valuable

materials.

Our company's products are shipped to all over the world, making

great contributions to environmental protection and resource

recycling around the world. At the same time our customers can make

considerable profits. This is the vision of our company and the

common wish of every customer.

Industry-Leading Recycling Systems by Xrido:

• Separation Tech: Air density separators, magnetic drums, eddy

current systems

• Size Reduction: Bag-breaking shredders, high-torque granulators

• Material Flow: Chain feeders, customized conveyor networks

• Quality Control: Ergonomic sorting platforms, precision baling

presses

Designed for construction debris & MSW processing, our machinery

optimizes material recovery efficiency.

Xrido Environmental – Engineering Circular Futures

We innovate in green technology through:

✓ Automated sorting solutions for complex waste matrices

✓ Full-spectrum recycling equipment manufacturing

✓ Smart integration of screening, separation, and size reduction

technologies

Core offerings range from trommel screens to magnetic recovery

systems, empowering waste-to-resource conversion worldwide.

It's our honor to be trusted by our customers. It's also the vision

of our company. We are constantly pursuing the satisfaction and

recognition from our customers. We are looking forward for every

opportunity of cooperation. We also provide is installation

direction and perfect after-sale service. We take every opinions of

our customers priciously. That's the most important way to improve

our service and customers' experience.