Aluminum Scrap Shredder For Automobile Wheels, Broken Bridge

Aluminum, Various Aluminum Products

Products Description

Aluminum Scrap Shredder For Automobile Wheels, Broken Bridge

Aluminum, Various Aluminum Products

Aluminum scrap shredder is a kind of equipment specially used for

processing aluminum scrap materials. In recent years, with the

enhancement of resource recycling awareness and the improvement of

environmental protection requirements, the demand for aluminum

scrap shredder has gradually increased. As a manufacturer

specializing in the manufacture of aluminum scrap shredders, we are

committed to providing customers with efficient and reliable

equipment to help the efficient recycling of resources.

Aluminum scrap refers to aluminum scrap generated during the

production and consumption process, including aluminum cans,

aluminum alloy wheels, aluminum profiles, etc. Aluminum is a

recyclable metal, and its recycling has significant economic and

environmental benefits. By recycling aluminum scrap, the

exploitation of natural resources can be reduced, energy

consumption can be reduced, and greenhouse gas emissions can be

reduced. The cost of recycling aluminum is much lower than the cost

of extracting aluminum from aluminum ore, and the recycling of

aluminum scrap has a good market prospect.

| | | | | |

| | | | | |

| | | | | |

| | | | | |

| | | | | |

| | | | | |

| | | | | |

| | | | | |

| | | | | |

Notes: 1. The number of blade claws, diameter, and thickness can be

customized according to the type of material and the size of the

discharge. 2. The output of the equipment will be different depending on the

type of material and the size of the discharge. 3. More information please contact us, we can custom the product on

your request. |

Scrap aluminum shredders are widely used in many industries,

including:

(1) Scrap metal recycling industry: Many scrap metal recycling

companies use scrap aluminum shredders to process aluminum

materials and improve resource recovery rates.

(2) Aluminum processing companies: Aluminum processing companies

generate a large amount of scrap aluminum during the production

process. The use of shredders can recycle these waste materials and

reduce production costs.

(3) Environmental protection industry: With the advancement of

environmental protection policies, more and more environmental

protection companies have begun to pay attention to the recycling

of scrap aluminum, and shredders have become one of their

indispensable equipment.

Scrap Metal Shredding & Crushing Line

1.metal recycling line adopts two-shaft metal shredder, hammer

crusher for crushing the scrap metal.

2.Use Dust collector and special structures to remove the fine

particle and dust during the crushing period.

3.The scrap metal recycling equipment separates the ferrous metal

by a magnetic separator.

4.(Optional)Eddy current separator is adopted by the waste

recycling machine to separate the non-ferrous metal from nonmetal

materials.

Core equipment:Double-shaft shredder,Hammer crusher,Magnetic

separator.

|

|

| Scrap Metal Shredder Sorting Line | Waste Aluminum Crushing Production Line |

|

|

| Water Radiator Crushing Sorting Line | UBC Aluminum Cans Decoating Machine |

Key equipment of metal crushing and recycling production line:

Other Metal Recycling Machine

Reliable and durable recycling technologies for material separation

and recovery,treatment of various types of solid waste and metal

scrap. Metal recycling can benefit your Enhance and economic value

, Help you improve recycling eliminate landfilling of waste.

With XRIDO’s ready-to-use spare parts library , you gain peace of

mind through seamless maintenance and reduced downtime.

Successful Project

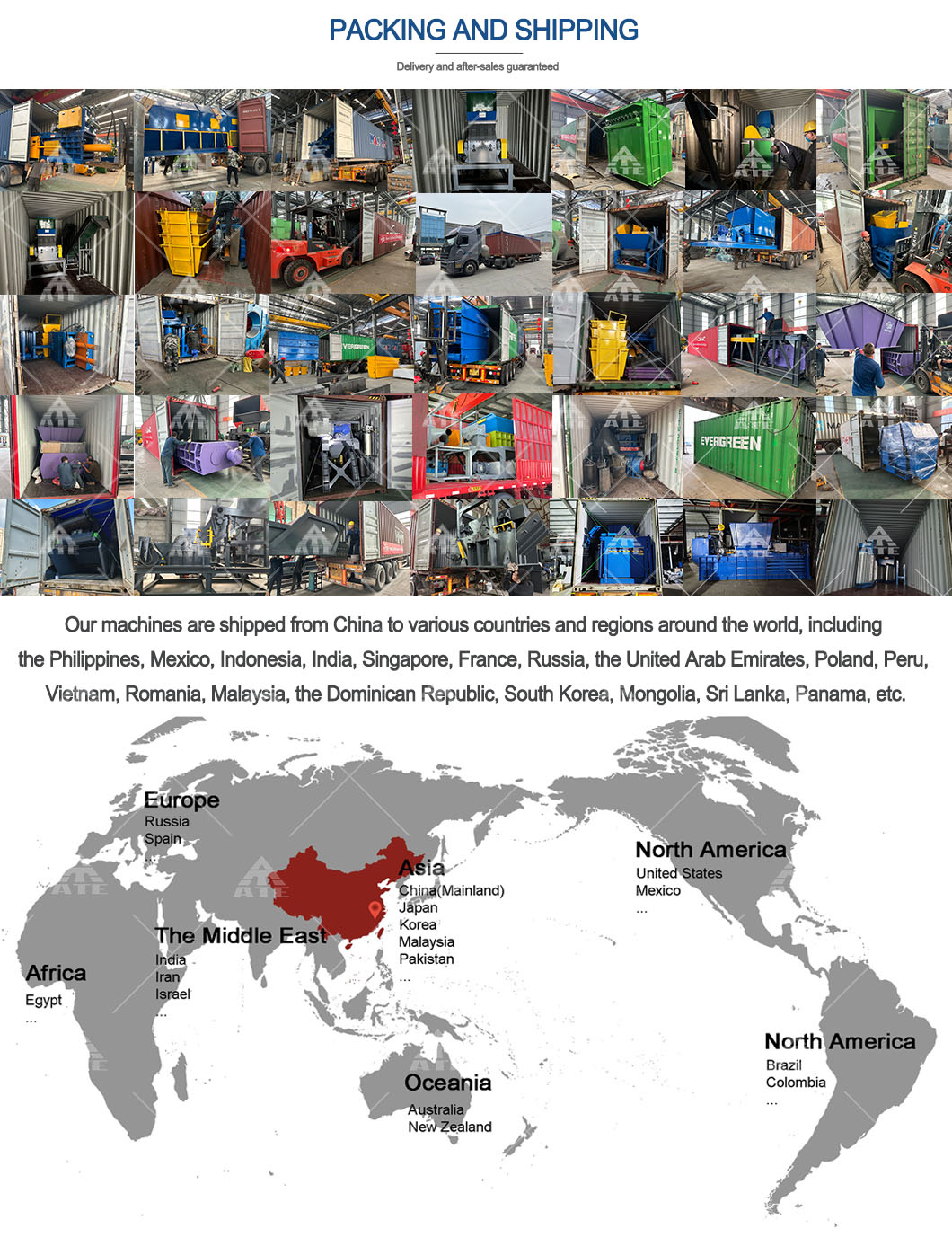

Our machine has passed ISO9001:2000, CCC,CE certification.Our

machines has already spread over the world.We can provide customers

with one-stop service and solutions, complete equipment, on-site

installation, and after-sales support.

Q1: Are you a factory or a trading company?

A1: We are a professional manufacturer in China, passed Alibaba

field certification.

Q2: How long is the warranty period?

A2: Normally 12 months. Except for wearing parts.

Q3: What’s your delivery time??

A3: We will arrange for shipping in factory within 15 working days

after receiving the advance payment.

We provide the entire waste sorting line, including factory design,

circuit routing, equipment placement, etc. Please feel free to

contact us for details. Welcome to factory to discuss business

cooperation.