Against the backdrop of the increasing awareness of global resource

recycling and environmental protection, HenanXrido Environmental

Protection Technology Co., Ltd., as a leading enterprise in the

industry, has always taken "innovation drives green development,

and technology protects our beautiful home" as its mission, deeply

engaged in the field of solid waste disposal and renewable resource

recycling, and is committed to providing customers with efficient,

environmentally friendly and intelligent one-stop solutions. With

its outstanding technical strength, rich product system and

high-quality services,Xrido has become a trusted brand in the

industry.

Since its establishment,Xrido has occupied an important position in

the fields of solid waste disposal, urban domestic waste sorting

and recycling, and renewable resource recycling equipment

manufacturing after years of steady development. The company has a

modern production base and advanced production equipment, and has

brought together a group of high-quality R&D, production and

management talents. With its accurate grasp of industry trends and

continuous technological innovation,Xrido has continuously launched

high-quality products and solutions that meet market demand, with

its business scope covering the whole country and gradually

expanding to the international market.

The company attaches great importance to technological research and

development and innovation, has established a complete R&D

system, and has carried out in-depth cooperation with many

universities and scientific research institutions to continuously

improve its own technical level. At present,Xrido has obtained a

number of national patents and authoritative certification

certificates. These patents and certificates are not only a strong

proof of the company's technical strength, but also lay a solid

foundation for the company in market competition.

One-stop solid waste disposal solution

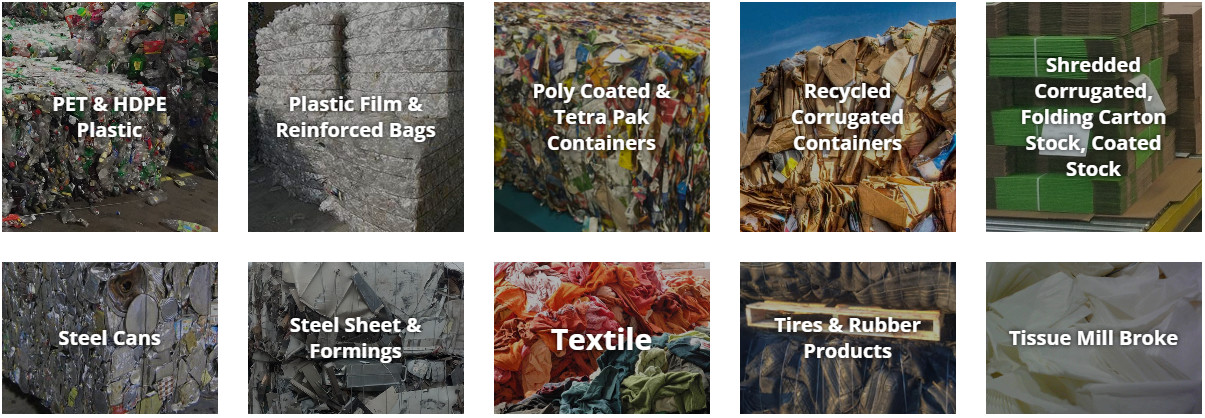

The one-stop solid waste disposal solution provided by Xrido covers

the whole process from solid waste collection, crushing, sorting to

final treatment. The company formulates personalized disposal

solutions for different types of solid waste, such as industrial

waste, construction waste, domestic waste, etc., to ensure that

solid waste is treated safely, efficiently and environmentally

friendly.

In terms of solid waste disposal equipment, Xrido has a series of

star products. The double-shaft shredder adopts a unique

double-shaft design and has a strong crushing capacity. It can

easily crush various large and hard solid wastes into small pieces.

It is suitable for the crushing of industrial waste, waste wood,

etc.; the industrial waste shredder is specially designed for

various types of waste generated in the industrial production

process, which can effectively improve the crushing efficiency and

reduce energy consumption; the solid waste crushing material

sorting machine can accurately sort the crushed solid waste and

separate materials of different materials for subsequent recycling

or harmless treatment; the RDF briquetting machine can make solid

waste into fuel rods with a certain calorific value to realize the

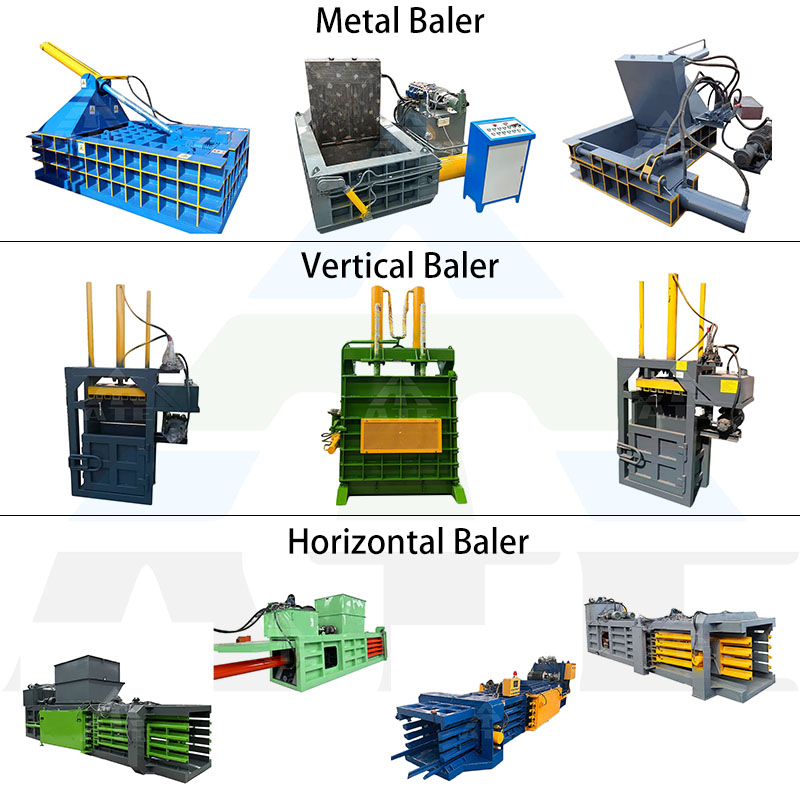

energy utilization of solid waste; the waste baler can compress

solid waste into compact blocks, which is convenient for storage

and transportation and reduces the floor space.

Waste crushing, sorting and recycling system:

| |

| Waste Metal Recycling System | Electronic Waste Recycling System |

| |

| Solid Waste Disposal System | RDF Briquetting System |

Renewable resource recycling solutions

With the increasingly severe problem of resource shortage, the

recycling of renewable resources has become an important way to

achieve sustainable development. Xrido focuses on the research and

development and production of renewable resource recycling

equipment, providing customers with complete renewable resource

recycling solutions to help the recycling of resources.

The company's renewable resource equipment is rich in variety and

excellent in performance. Metal shredders and metal crushers can

quickly break scrap metal into small pieces, improving the metal

recycling efficiency; magnetic separators use the principle of

magnetism to separate ferromagnetic substances from crushed metal

materials; eddy current separators are used for non-ferrous metals

such as aluminum and copper, and achieve efficient sorting through

eddy current effect; metal balers and metal shearing equipment can

compress and shear the recycled metals, making it easier to store

and transport, and reducing recycling costs.

Metal Crushing Recycling Plant

We can customize metal crushing and recycling production line for

you.

| |

| Scrap Metal Shredder Sorting Line | Waste Aluminum Crushing Production Line |

| |

| Water Radiator Crushing Sorting Line | UBC Aluminum Cans Decoating Machine |

Other Metal Recycling Machine

Renewable resource recycling solutions

With the increasingly severe problem of resource shortage, the

recycling of renewable resources has become an important way to

achieve sustainable development. Xrido focuses on the research and

development and production of renewable resource recycling

equipment, providing customers with complete renewable resource

recycling solutions to help the recycling of resources.

The company's renewable resource equipment is rich in variety and

excellent in performance. Metal shredders and metal crushers can

quickly break scrap metal into small pieces, improving the metal

recycling efficiency; magnetic separators use the principle of

magnetism to separate ferromagnetic substances from crushed metal

materials; eddy current separators are used for non-ferrous metals

such as aluminum and copper, and achieve efficient sorting through

eddy current effect; metal balers and metal shearing equipment can

compress and shear the recycled metals, making it easier to store

and transport, and reducing recycling costs.

Success Cases

Xrido's products and solutions have been successfully applied in

many projects and have achieved significant economic and social

benefits. In a solid waste disposal project in a large industrial

park, the one-stop solid waste disposal solution provided by Xrido

has achieved efficient treatment and resource utilization of

industrial waste in the park through the reasonable configuration

of double-axis shredders, solid waste crushing material sorting

machines and other equipment, which can reduce a large amount of

solid waste landfill every year, and at the same time recycle a

large amount of renewable materials, saving a lot of solid waste

treatment costs for park enterprises; in a domestic waste sorting

and recycling project in a certain city, the company's urban

domestic waste recycling equipment is combined with AI technology

to greatly improve the sorting accuracy and recycling rate of

domestic waste, effectively improve the urban environment, and make

positive contributions to the sustainable development of the city.